Hot selling MP45 solution vinyl resin

Product Description

Appearance: White thermoplastic powder, inodorous, no toxin

BRIEF INTRODUCTION:

MP serial chlorinated resins are copolymers of vinyl chloride and vinyl isobutyl ether. They can be used as base resin for air-drying paints or other physical drying paints. At present, only Germany, USA, Japan and China can produce these items. According to the international convention, chlorinated rubbers were forbidden to produce from 2004. MP series chlorinated resins, as base resin for heavy duty anticorrosion paints, can replace chlorinated rubber. They have broad prospects with their high ratio of quality to price and environmental protection advantage.

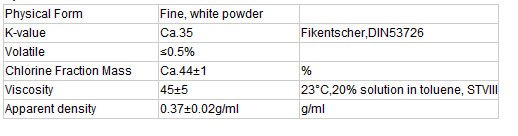

Specification:

Product Advantages:

Excellent hydrolysis stability, resistant to acid, alkali and salt.

Good compatibility with other resins

Good solubility in hydrocarbon oraromatic solvents

Good pigment wetting ability

Good adhesion on plastic films

Good heat stability ( it is very important during sterilization)

Application:

CMP45 is the polymer of 75% chloroethylene and 25% vinyl isobutyl ether. The vinyl isobutyl ether offers the product good link function.In the ink processing, CMP45 is the mainly used resin. It is mostly used in solvent ink processing, especially the plastic compound ink. It is the very good link material.

Packaging & Shipping

Package and storage:

- Packed in the kraft bag with PE liner. 20kgs/bag.

- Avoid being crushed while storing and transferring. Stored away from heat and moisture.