For Friction Wollastonite

Product Description

WOLLASTONITE for friction

Characteristics :

Ceramic fillers Wollastonite

Wollastonite in Metallurgy application

Wollasonite in Welding application

Wollsatonite in Ceramics application

Wollastonite in Paints and Coatings application

Wollastonite in Friction material application

Wollasonite in Construction application

Wollastonite in Rubber and Plastic application

Wollastonite in Electronics application

- SPECIFICATION

- Properties and application

Adding appropriate wollastonite (either medium-grade or low-grade) in ceramic raw material is beneficial to greatly reduce firing temperature and shorten firing time of finished product, achieve low-temperature once firing, save a great deal of fuel and product cost. Because wollastonite products do not include alkali metal, it shows excellent electric insulation property, as well as high impact strength resistance and dimensional stability, has a wide application in the precision ceramic industry and art ceramic industry. In glaze mud material, wollastonite, instead of white pigment, can increase gloss of glaze, reduce viscosity of glaze mud and mitigate cost greatly. In ceramic products, wollastonite can avoid fracture, hair cracking, breakage or defects of ceramic glaze. Due to linear thermal expansion, it can reduce the flexural degree of products.Our wollastonite powder for ceramic is effective to greatly reduce firing temperature, shorten firing time, achieve low-temperature once firing, save a great deal of fuel and reduce product cost, as well as to improve mechanical property, reduce cracks and flexure of product, increase gloss of glaze, improve strength and yield of products further.

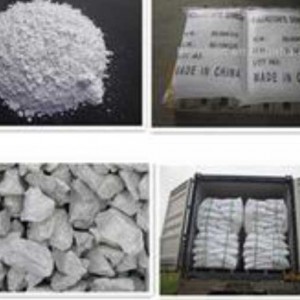

Package: 50KGS net per bag or 1-1.2 MTS net per jumbo bag with pallet

Loading: 24 mts net per 20 feet container with pallet